a1 - SHEET METAL PLANT

100,000 SQUARE FEET FACILITY

Our On-stop-shop started operations since 2015 providing Sheet metal fabrication, welding, powder coat (up to 2,100 salt spray hours) and final assemblies to customers in Northern Mexico and USA. This facility is located in Monterrey, Mexico; only 138 miles from the U.S. border.

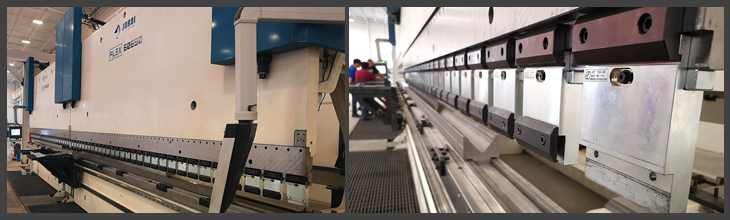

a2 - MEDIUM FABRICATION PLANT

130,000 SQUARE FEET FACILITY

Our Medium Fab plant opened its doors in 2019, specializing in high-value, repetitive welding components weighing up to 20 tons. Our facility is equipped with a range of machinery, including a 12-meter press brake, 15KW fiber and plasma cutters , 40 welding cells, machining , liquid paint and batch powder coating system for up to 15 meters in length.

A3 - assembly PLANT

50,000 SQUARE FEET FACILITY

Our conveyor assembly plant started operations in late 2021, making it our first value-add facility to assemble components such as motors, belts, plastics, rollers, and more. Our production line has the capacity to assemble up to 2,000 conveyors per month depending on the model.

a4 - HEAVY FABRICATION PLANT

OUR NEW 260,000 SQUARE FEET FACILITY EXPANSION

Our new expansion is set to start operations in 2024, providing an increase in capacity and volume for our customers with requirements exceeding 20 metric tons for both repetitive parts and one-shot projects .

PLANT 1 - Automotive plant

PLASMA CUT, STAMPING, MACHINING AND TOOL SHOP

Established since 1995, our facility has a long time presence with automotive and agroindustries manufacturing in México providing low cost solutions with a skilled workforce.

VALUE ADD BENEFITS TO OUR CUSTOMERS

Our value proposition is to become your one-stop-shop